Backed by decades of experience and millions of square feet of manufacturing facility construction projects delivered nationwide, ARCO National Construction’s deep industry expertise has made us a trusted partner for developers, manufacturers, and end-users alike. Our responsive design-build approach ensures cost-effective, high-performance facilities that enhance productivity and operations.

Design-build solutions for successful manufacturing facility construction

As one of the nation’s largest design-build general contractors, ARCO National Construction delivers turnkey manufacturing facility construction solutions tailored to meet the unique needs of complex production environments across the U.S. From initial planning through completion, we design and build facilities that support efficient operations, future growth, and long-term success.

100

Manufacturing Facility Projects Constructed

18

Square Feet of Manufacturing Projects Completed

SUPERIOR MANUFACTURING FACILITY CONSTRUCTION EXPERTISE

Every manufacturing facility has specific operational goals and challenges. ARCO’s team brings technical mastery and industry insight to every project, no matter the sector. We deliver solutions for a broad range of manufacturing types, including:

- Automotive

- Consumer Products

- Packaging

- Alternative Energy

- Medical Device

- Aerospace

- Chemical

- Cosmetics

- Plastics

- Pulp & Paper

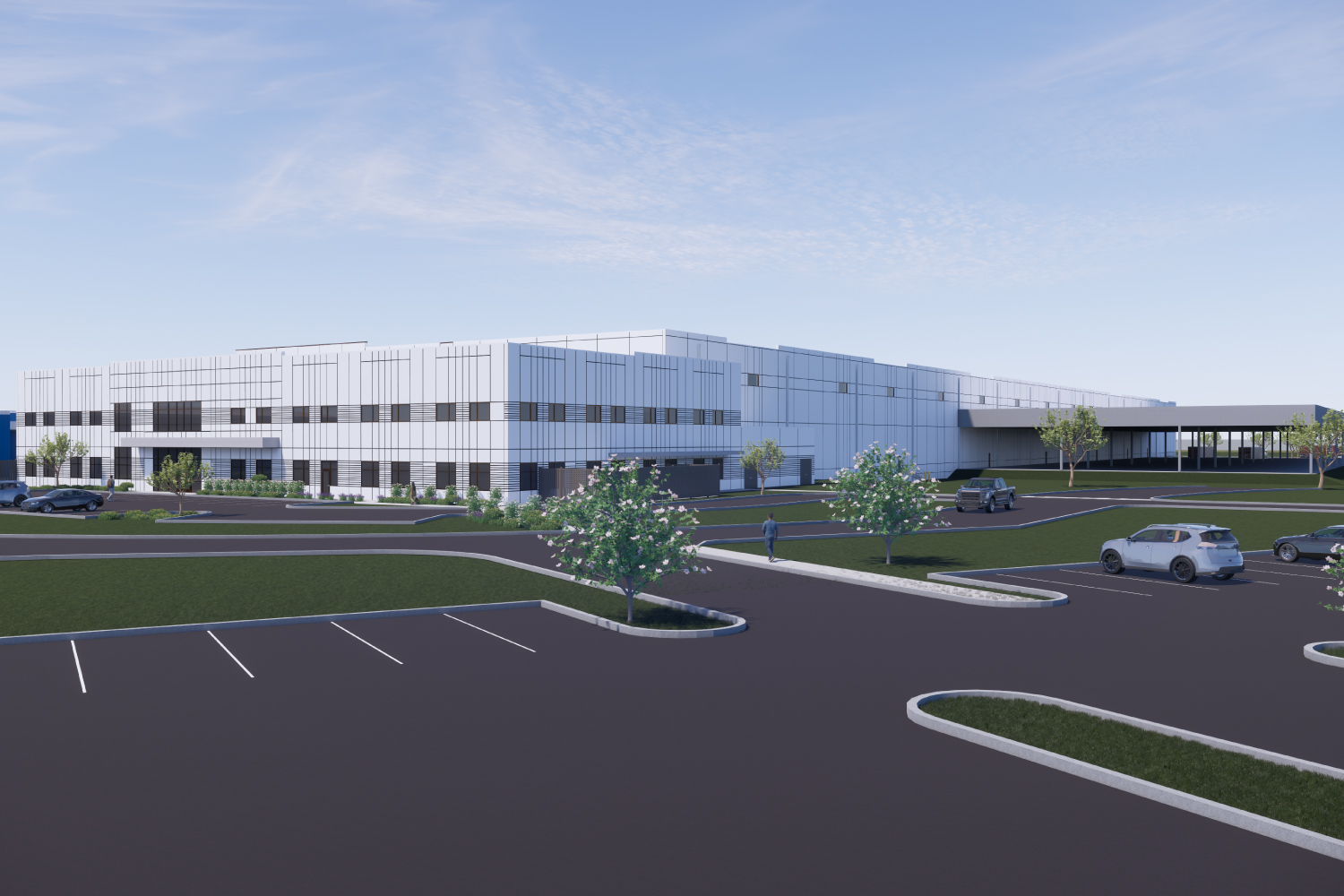

Featured Manufacturing Facility Projects

ARCO is proud to support manufacturers across diverse industries with high-performance facilities designed and built for success. Our portfolio includes a wide spectrum of manufacturing facility construction projects from advanced production campuses to specialized manufacturing plants that support cutting-edge processes and technologies.

ARCO’s Manufacturing Facility Construction Value

Our design-build process minimizes risk, maximizes value, and gives you cost and schedule confidence from day one.

GET IN TOUCH.

Contact ARCO for expert facility solutions that optimize design, cost, and performance, ensuring a seamless experience from start to finish.

Solutions for Every Stage of Your Manufacturing Facility Construction Project

What types of manufacturing facilities does ARCO deliver?

ARCO designs and builds complex manufacturing facilities across sectors including automotive, aerospace, consumer products, packaging, medical devices, advanced industrial manufacturing, and more.

Why choose a design-build approach for manufacturing projects?

Design-build streamlines decision-making, accelerates schedules, improves cost certainty, and reduces change orders by aligning design and construction from day one.

Can ARCO support highly technical or regulated manufacturing environments?

Yes. Our teams deliver facilities with specialized requirements such as precision foundations, advanced HVAC systems, process utilities, cleanrooms, and controlled environments.

What preconstruction services does ARCO provide for manufacturing projects?

We offer site feasibility analysis, utility and infrastructure assessments, cost modeling, constructability reviews, and risk mitigation planning before construction begins.

How does ARCO support site selection and operational planning for manufacturing projects?

Our team evaluates access, logistics, material flow, and utility capacity to ensure the facility supports efficient operations and long-term performance.

What makes a manufacturing facility successful long-term?

Successful facilities integrate scalable infrastructure, robust MEP systems, efficient production layouts, and flexibility to adapt to future growth or process changes.

Can construction occur while my manufacturing operations remain active?

Yes. ARCO frequently executes phased construction and expansion projects while maintaining ongoing manufacturing operations.

Why partner with ARCO National Construction for manufacturing construction?

With decades of experience and millions of square feet delivered nationwide, ARCO combines technical expertise with a disciplined design-build process to deliver efficient, high-performance manufacturing facilities.

Manufacturing Facilities Design & Construction Considerations

Successful manufacturing facility construction depends on early planning, technical expertise, and an in-depth understanding of how building systems interact with production operations. From site selection and structural design to utility infrastructure and long-term flexibility, each component must be carefully coordinated to support efficiency, safety, and future growth. An experienced design-build partner plays a critical role in aligning these elements from day one.

Site Selection

Site selection is a foundational consideration in manufacturing facility construction. The right location must support efficient logistics, reliable access to labor, proximity to suppliers and customers, and compatibility with zoning and regulatory requirements. Utility availability, transportation infrastructure, and long-term expansion potential also play a major role in determining a site’s viability. Decisions made at this stage have a direct impact on construction cost, schedule, and operational efficiency.

ARCO’s site feasibility services help manufacturing owners evaluate potential sites early in the process by providing site-specific cost insight, assessing transportation access and infrastructure, and identifying potential challenges or risks before they impact the project. By addressing these factors upfront, ARCO helps clients avoid delays, reduce unforeseen costs, and select sites that best support long-term operational success.

Structural Design

Structural design is a critical component of manufacturing facility construction, as facilities must support heavy machinery, production lines, and dynamic loads while remaining adaptable to changing processes. Clear heights, column spacing, floor slab capacity, and vibration control all influence how efficiently a manufacturing operation functions. A well-designed structural system not only supports current production needs but also allows for future equipment upgrades and process changes.

ARCO designs and constructs structural systems tailored to the specific demands of each manufacturing operation. Our team accounts for equipment loads, crane requirements, production flow, and future automation needs during the earliest planning stages. Through our integrated design-build approach, ARCO ensures structural systems align with operational goals while maintaining flexibility for future growth.

Utility Infrastructure

Manufacturing operations rely on robust and reliable utility infrastructure to maintain consistent production. Electrical capacity, HVAC, water, gas, compressed air, and process piping systems must be carefully coordinated to support specialized equipment and environmental requirements. Inadequate utility planning can lead to operational inefficiencies, costly retrofits, and downtime.

ARCO works closely with manufacturers to design utility systems that support both current operations and long-term scalability. By coordinating utility requirements early in the design process, ARCO delivers manufacturing facilities with high-capacity electrical systems, specialized climate control, and infrastructure designed for reliability and redundancy. This proactive approach reduces rework, controls costs, and supports uninterrupted operations once the facility is online.

Overall Flexibility & Future Growth

Flexibility is essential in modern manufacturing facility construction. As production methods evolve, facilities must be able to accommodate new equipment, automation, and changes in workflow without significant disruption. Designing for adaptability from the outset protects long-term investments and ensures facilities remain competitive over time.

ARCO designs manufacturing facilities with flexibility built into every phase of the project. Our approach considers future expansion, increased floor loads, scalable utility systems, and layouts that can adapt to automation and advanced manufacturing technologies. By planning for change early, ARCO helps manufacturers maintain operational efficiency and extend the lifespan of their facilities.

”Throughout the project, ARCO’s proactive approach, effective communication, and commitment to quality were key to keeping the project on schedule and under budget. Their ability to respond to real-time design changes and seamlessly integrate evolving requirements into the construction process was instrumental in maintaining forward momentum.

Cory RoeslerFaith Technologies, Inc.