ARCO’s unparalleled industry knowledge sets us apart as a leading cannabis contractor and trusted partner on projects nationwide. Our experience across project types consistently results in the most functional and cost-effective cannabis facilities.

Design-build solutions for successful cannabis facility construction

ARCO National Construction brings extensive experience in building cannabis cultivation, processing, distribution, and dispensary facilities across the country. As a leading cannabis construction company, we are dedicated to delivering value-driven solutions tailored to our customers’ cannabis design and construction needs.

70

Cannabis & CEA Facility Projects Constructed

13

Square Feet of Cannabis & CEA Projects Completed

SUPERIOR INDUSTRY EXPERTISE

Whether it’s a new, state-of-the-art grow facility or the conversion of an existing space into a medical marijuana dispensary, our team of design and construction experts have the knowledge and experience to bring our cannabis clients’ ideal facility to life.

- Grow & Cultivation

- Process & Manufacturing

- Vertically Integrated

- Distribution

- Dispensaries

Featured Cannabis Projects

In an industry where expertise is essential, ARCO National Construction is proud to be a trusted advisor to some of the biggest names in the business.

GET IN TOUCH.

Ready to kick off your cannabis facility project? We're here to connect and help you get started smoothly.

”ARCO did a tremendous job from design kickoff through project completion. They were crucial in working through local government approvals and a true partner when typical construction issues arose. We are very proud of the facility ARCO built.

Drew LammertLSL Management

Cannabis Facility Design & Construction

There are many design and construction details that must be considered to achieve a successful cannabis facility design and development. Grow operations, production processes, space ratios, as well as permitting and zoning requirements are all elements that should be explored in the earliest stages to ensure that a cannabis facility is designed and constructed in the most functional and cost-effective manner. Partnering with an experienced contractor that is actively engaged throughout the project will ensure that the very best design and construction decisions are made, resulting in a superior finished product and the very best customer experience.

Facility Types

There are three main types of cannabis facilities, including grow and cultivation facilities, vertically integrated facilities, and dispensaries. Grow and cultivation facilities are climate-controlled and support year-round crop growth and cultivation. Vertically integrated facilities combine cultivation, extraction, post-processing, consumables manufacturing, and quality assurance testing labs. Dispensaries serve as cannabis retail locations, often including office and processing spaces.

- Grow & Cultivation

- Vertically Integrated

- Dispensary

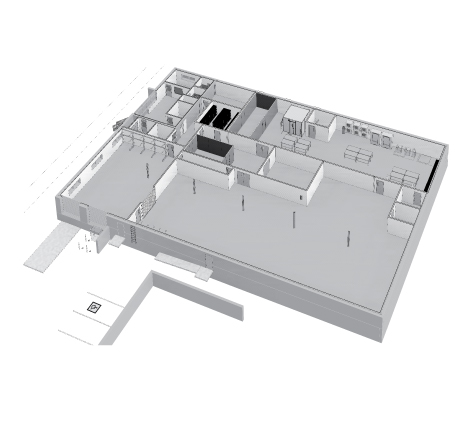

Facility Design & Layout

Understanding grow operations and production processes is essential to designing an efficient and functional cannabis facility. Improper ratios of space, irrational flow, and a flawed system design can adversely impact overall productivity and efficiency. Design factors such as the number of plants per square foot, height of plants at harvest, and irrigation methods should all be considered. Additionally, grow room conditioning plays a major role in the mechanical design of a facility. Whether or not a space has CO2 supplementation or natural ventilation, the type of lighting on the canopy, and the number of grow room tiers can all affect the functionality, design, and budget of a cannabis facility. Collaboration between the design team, contractor, and equipment vendors in a project’s early stages is key to avoiding potentially costly and time-consuming design change orders throughout construction.

Zoning & Permitting

Because regulations vary by city and state, the zoning and permitting process associated with cannabis construction can potentially be long and complicated. However, an experienced contractor with knowledge of the permit process in a variety of national markets can expedite identifying the critical path to eliminate unforeseen delays and begin construction as soon as possible.

Environmental Controls

Creating a stable, controlled environment that can produce repeatable results is one of the most important elements of cannabis construction. Cultivation and vertically integrated facilities have to be precisely controlled for humidity, lighting, airflow, and temperature to prevent mold or mildew growth or pest infestation.

Facility Systems

Facility systems such as lighting, electrical service, HVAC, and fire protection are also important elements to consider regarding cannabis construction. In addition to evaluating options and standards associated with these systems, it is also critical to understand code requirements to avoid design change orders and occupancy delays. For example, in addition to the proper lighting type for efficiency and effectiveness, proper design and layout must be considered to avoid plants getting too much or not enough light. Additionally, because of the chemicals often used during extraction, obtaining fire protection permits can take longer than usual.

Automation

Implementing automation equipment into a cannabis facility can be highly beneficial when it comes to overall efficiency and navigating complicated operations. Fully automated irrigation systems to optimize water usage, lighting to regulate intensity, and climate controls such as temperature, air velocity, and humidity can all decrease energy costs. Automated processes can also help minimize potential damage from manual interactions with plants. Collaboration between the design team, contractor, and equipment vendors in a project’s early stages is key to avoiding potentially costly and time-consuming design change orders throughout construction.

Design-Build Delivery

Partnering with a qualified design-build contractor like ARCO with experience in complex project types like cannabis is essential for success. Design-build delivery helps clients navigate strategic design decisions and strategic planning for their cannabis facilities. Additionally, unlike traditional delivery methods that treat the phases of design and construction sequentially, the design-build process combines quality of design and construction, management of capital expense, and adherence to schedule all under a single point of responsibility. Preliminary design is completed during the proposal process, and cannabis facility users benefit now more than ever from the speed at which design-build delivery moves.

Contact Us